Description

They are used in many closed loop HVAC applications. Systems with pressure independent control valves do not need to be balanced and rebalanced during commissioning. They regulate and maintain a constant flow to the coil as water pressure in the system varies with the changing loads.

This delivers better comfort, increases energy efficiency, reduces actuator operation and reduces expensive call backs. Pressure independent valves allow the system to perform better. With the right flow to each coil, boilers and chillers are most efficient

PICV obtain optimal results because only the necessary amount of hot water (in GPM) and chilled water (in GPM) is delivered to the heating and cooling coils. Standard 2-way control valves allow for overflow and underflow especially if the CV is oversized or undersized. This generates excess water to the pump to compensate for their inaccuracy, which increases pumping cost.

The actuators on PICV valves do not cycle as often as standard 2-way valves to compensate for pressure changes in the system that impact the flow, which results in energy savings.

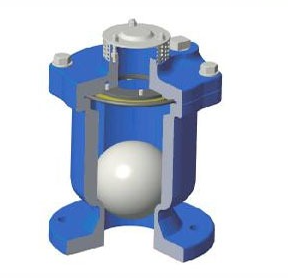

Pressure independent control valves integrate dynamic balancing and control functions into a single product. They respond to changes in pressure in order to maintain the desired flow. The differential pressure regulator part of the valve incorporates a rubber diaphragm that is moved by pressure differential and a spring. It is exposed to the inlet pressure on one side, and the outlet pressure on the other. As the diaphragm moves, it operates a valve that keeps the pressure drop across the ball valve constant regardless of system pressure changes. The ball valve section then modulates to maintain room setpoint so the flow is varied by room demand, not by changes in system pressure.

In conclusion, pressure independent control valves make installation and commissioning simpler. They deliver a constant flow even as loads change and valves in the system open and close. This reduces actuator operation and delivers better zone control. They also reduce costs and make the entire system work better because with the right flow to each coil, pumps and chillers operate efficiently.